MK-SAC – SUB COMPACT IM AUTOLOAD CARTONER

Furthermore, the MK-SAC features a servo-driven rotary feeder that is simple to set-up and can reach 100 cpm via intermittent motion operation. The HMI screens on the MK-SAC are intuitive and provides your production team with accurate fault diagnostics, access to all motors, cylinders, and sensors as well as easy homing guides for quick set-up and troubleshooting.

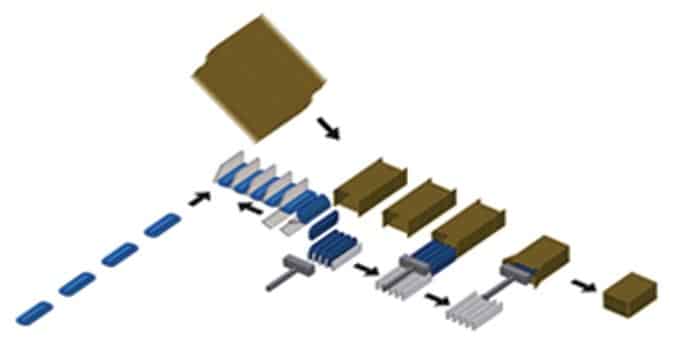

Offers an economical solution for low-speed applications. Loading Funnels with servo driven pushers end load product into the carton. Only erects cartons when needed reducing energy costs. Intuitive screens allow access to servo motor control, recipe changes, machine operation statistics and more. The ultra compact MK-SAC allows you to save valuable floor space.Key Features

Intermittent Motion Infeed System

Servo Driven Loading System

Intermittent Motion Rotary Feeder

Intuitive Allen Bradley PanelView HMI

Small Footprint

Code daters, ink/laser jet printers, and bar code readers can all be mounted on the MK-SAC. Allows for small depth cartons. Siko counters, ratchet handles, and visual scales can all be added to aid in changeover. Handles square cartons with ease as the carton will be prebroken slightly before placement into the main chain conveyor. The MK-SAC can be constructed using stainless steel or equivalent for wash-down capability.Optional Features

Mounting Locations for Optional Equipment

Stacked Chain Arrangement

Quick Changeover Options

Prebreak Carton Opening

Wash-down Construction

Applications

Bars of Product

Multi or single packs of bars are easily collated by the MK-SAC.

Snack Foods

The MK-SAC is ideal for integrating with upstream vertical baggers.

Flow Wrap Packages

Low to mid speed flow-wrapping machines will seamlessly integrate with the MK-SAC.

Health Products

Single or dual lanes to handle your health products.

Stick Packs

The MK-SAC can be deigned to collate and carton two lanes of stick packs.

Partners & Associations